GYLON® Gaskets & Sheets

High performance PTFE gasketing

Garlock GYLON® gasketing is a family of severe service PTFE gasketing materials manufactured using a proprietary process that imparts unique physical properties that are not obtainable through conventional manufacturing methods.

The innovative GYLON® manufacturing process reorients the PTFE and fillers in a way that increases the material’s tensile properties and decreases the creep relaxation problems that usually plague PTFE products. In addition, the mixing process creates a homogenous material with consistent, superior physical properties that, unlike inferior skived PTFE sheet gaskets, do not fluctuate from one side of the sheet to another. Plus, our patented thermal bonding process allows us to fabricate gaskets of nearly any size.

Designed for severe chemical service, GYLON® gaskets are color-coded for easy identification and provide superior sealability to reduce process and media loss and fugitive emissions. They also reduce creep and cold flow characteristics.

GYLON® Gaskets & Sheets

GYLON® Style 3501-E

GYLON® Style 3501-E (brick red) is a high performance gasketing material made of multi-layered PTFE for permanent resilience. It’s the first choice for universal applications in the chemical and petrochemical industries. GYLON® Style 3501-E is a modified PTFE gasketing material and optimized for the European market.

Features & Benefits

-

20 N/mm2 minimum load (160 N/mm2 maximum load)

-

Wide temperature range

-

Stopped cold flow

-

High resilience

-

High pressure & vacuum duties

-

Excellent chemical resistance

-

Available with inner-/outer eyelet

-

Good electrical insulating properties

-

Unlimited shelf-life

-

Weather and UV resistant

Specifications

- Temperature: -268 °C to +260 °C

- Pressure: up to 83 bar

- Shore hardness: D68

- Available Thicknesses: 0.8mm, 1.0mm, 1.6mm, 2.0mm, 3.2mm, 4.8mm, 6.4mm (more thicknesses on request)

- Compressibility (ASTM F36) 7-12%

- Recovery (ASTM F36) 40%

- Fluid Services: Strong acids (Except Hydrofluoric), Steam, Solvents, Hydrocarbons, Chlorine and Cryogenics

- Filler: Silica

- GYLON® 3501-E contains iron oxide (≤ 0,1%)

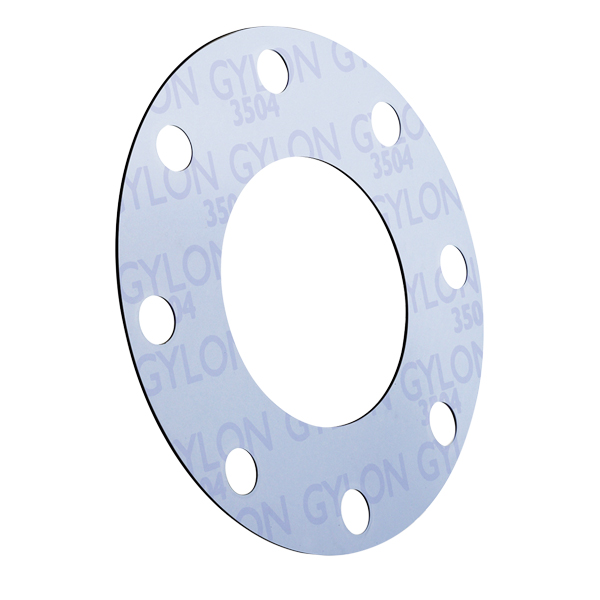

GYLON® Style 3504

GYLON® Style 3504 is a high performance gasketing material made of multi-layered PTFE for permanent resilience. It is highly compressible and flexible and especially suitable for low-stress components requiring low bolt torque loads, i.e. enameled and plastic flanges, glass tubes, GRP (Glass Reinforced Plastic) and FRP (Fiberglass Reinforced Plastic).

Features & Benefits

-

Recommended for glass lined flanges

-

10 N/mm2 minimum load (150 N/mm2 maximum load)

-

Large working range

-

Wide temperature range

-

Stopped cold flow

-

High resilience

-

High pressure & vacuum duties

-

Excellent chemical resistance

-

Available with inner-/outer eyelet

-

Good electrical insulating properties

-

Unlimited shelf-life

-

Weather and UV resistant

Specifications

- Temperature: -268 °C to +260 °C

- Pressure: up to 55 bar

- Shore hardness: D59

- Available Thicknesses: 0.8mm, 1.0mm, 1.6mm, 2.0mm, 3.2mm, 4.8mm, 6.4mm (more thicknesses on request)

- Compressibility (ASTM F36) 25-45%

- Recovery (ASTM F36) 30%

- Fluid Services: Moderate concentrations of acids, some caustics, Hydrocarbons, Solvents, Hydrogen peroxide, Refrigerants and Cryogenics

- Filler: Aluminosilicate microspheres

GYLON® Style 3510

GYLON® Style 3510 is a high performance gasketing material made of multi-layered PTFE for permanent resilience and has the broadest chemical resistance. GYLON® Style 3510 is the preferred choice for extremely aggressive media including hydrofluoric acid, aluminum fluorides, chlorine/alkali, caustic potash solutions and electroplating baths.

Features & Benefits

-

20 N/mm2 minimum load (150 N/mm2 maximum load)

-

Higher chemical resistance than 3501-E/3504

-

Wide temperature range

-

Stopped cold flow

-

High resilience

-

High pressure & vacuum duties

-

Excellent chemical resistance

-

Available with inner-/outer eyelet

-

Good electrical insulating properties

-

Unlimited shelf-life

-

Weather and UV resistant

Specifications

- Temperature: -268 °C to +260 °C

- Pressure: up to 83 bar

- Shore hardness: D75

- Available Thicknesses: 0.8mm, 1.0mm, 1.6mm, 2.0mm, 3.2mm, 4.8mm, 6.4mm (more thicknesses on request)

- Compressibility (ASTM F36) 7-12%

- Fluid Services: Strong caustics, Moderate Acids, Chlorine, Gases, Water, Steam, Cryogenics, Hydrocarbons fluoride and Aluminum

- Filler: Barium Sulfate

GYLON® Style 3545

GYLON® Style 3545 is a high performance gasketing material made of multi-layered PTFE for permanent resilience. This gasket material manufactured from soft compressible micro-cellular PTFE outer layers with a hard PTFE pressure resistant central layer, homogeneously sintered together. GYLON® Style 3545 is also ideal for uneven surfaces and has the excellent chemical resistance of 100% PTFE at the same time.

Features & Benefits

-

17 N/mm2 minimum load (140 N/mm2 maximum load)

-

Recommended for glass lined flanges

-

Wide temperature range

-

Stopped cold flow

-

High resilience

-

High pressure & vacuum duties

-

Excellent chemical resistance

-

Available with inner-/outer eyelet

-

Good electrical insulating properties

-

Unlimited shelf-life

-

Weather and UV resistant

Specifications

- Temperature: -268 °C to +260 °C

- Pressure: 83 bar

- Shore hardness: A60

- Available Thicknesses: 1.6mm, 2.0mm, 3.2mm, 4.8mm, 6.4mm (more thicknesses on request)

- Compressibility (ASTM F36) 60-70%

- Recovery (ASTM F36) 15%

- 100% Pure PTFE (No filler)

Find item-numbers and specifications in our webshop: GYLON® Gaskets & Sheets

Downloads

- Declaration of Conformity FDA

- Letter of Conformance – Animal Derivates Ingredients – ADI

- Declaration of Conformity – Phthalate free, Bisphenol free

DIN EN 13555

- GYLON® Style 3501E – 2mm

- GYLON® Style 3501E – 3.2mm

- GYLON® Style 3504 – 2mm

- GYLON® Style 3504 – 3.2mm

- GYLON® Style 3510 – 2mm

- GYLON® Style 3545 – 2mm

FOOD SAFE – EC1935/2004, EC 10/2011 conformity

Garlock GmbH

Falkenweg 1

41468 Neuss

Germany

+49 2131 349-0

garlockgmbh @ garlock.com

© 2025 Garlock GmbH, Germany

![]() An ENPRO Company

An ENPRO Company

www.garlock.com

Garlock Europe Webshop

www.garlock.eu.com

Career Site Europe

www.garlock-karriere.de/en