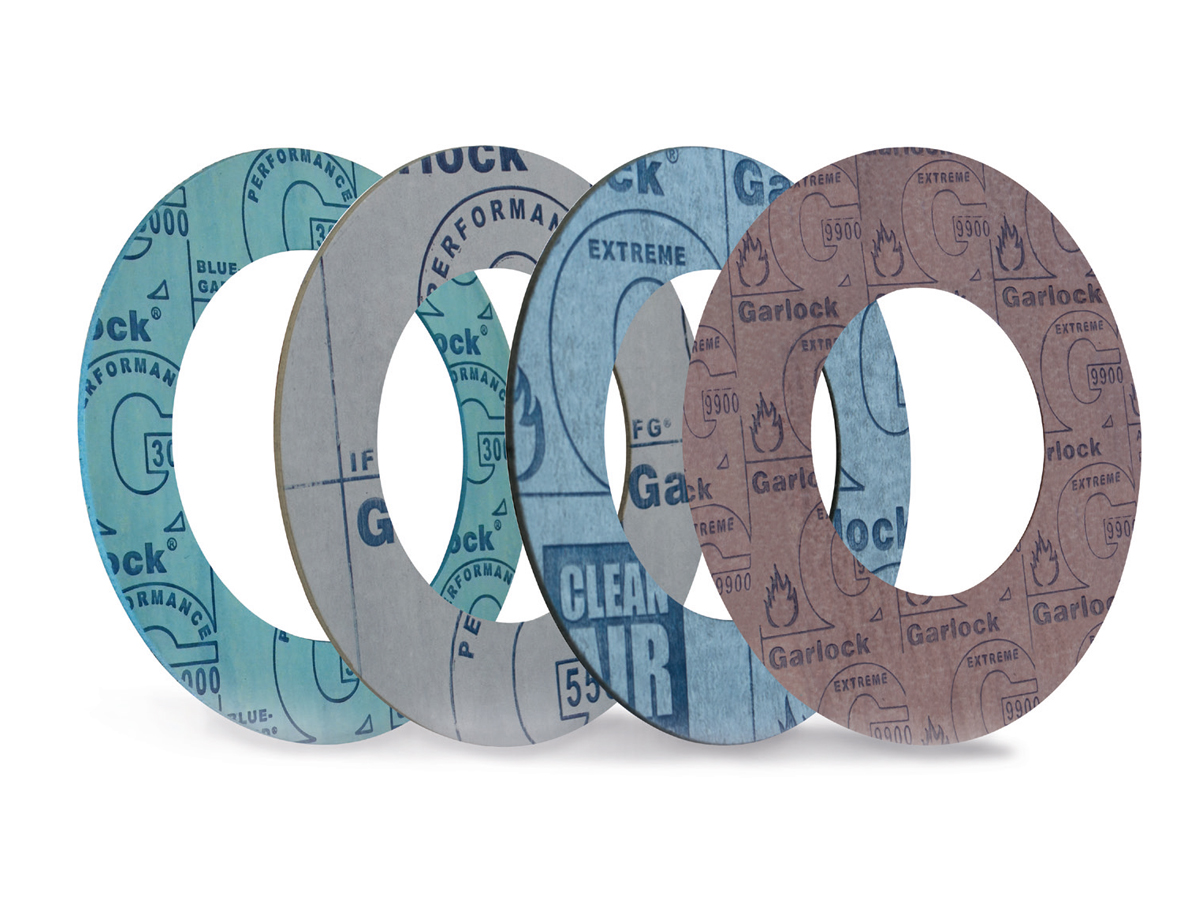

Fiber Gaskets & Sheets

Improved sealing capabilities and superior torque retention

For decades, Garlock fiber gaskets have been effectively used in the machine building industry, the chemical processing, supply facilities and power plants all over the world.

Continuous quality controls on key process steps and innovative production techniques at our production locations guarantee a constantly high quality and availability of the products. Many products are available from stock in Neuss and can be cut to the desired dimensions due to state-of-the-art cutting and punching machines.

Fiber Gaskets & Sheets

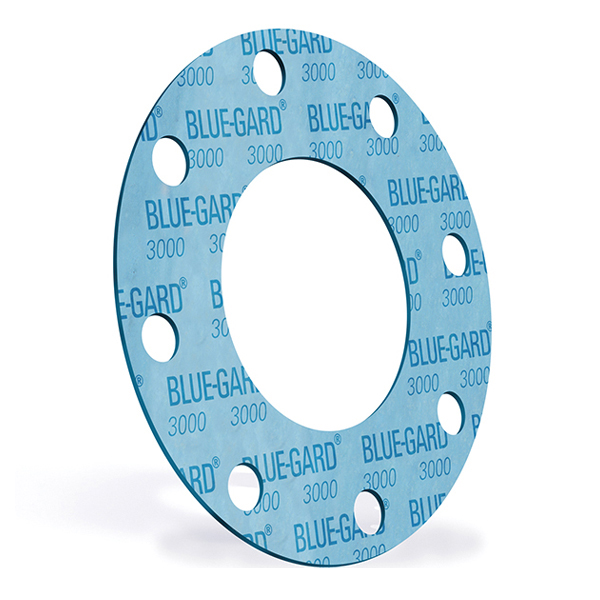

BLUE-GARD® 3000

Gasketing material made from a unique blend of fiber and fillers. Excels in a wide range of industrial applications.

Certificates

- TA-Luft

- DIN EN 13555 characteristics

- ABS (American Bureau of Shipping)

- API

- ISO 10497 (Fire-Safe)

Features & Benefits

-

Excellent sealability

-

Improved torque retention

-

Drastically lowered emissions levels

-

Cuts operational costs through reduced waste, maintenance, stocked inventory, fluid loss, and energy consumption

Specifications

- Maximum Temperature: 371 °C / 700 °F

- Continuous maximum Temperature: 205 °C / 400 °F

- Minimum Temperature: -73 °C / -100 °F

- Maximum Pressure: 70 bar / 1000 psig

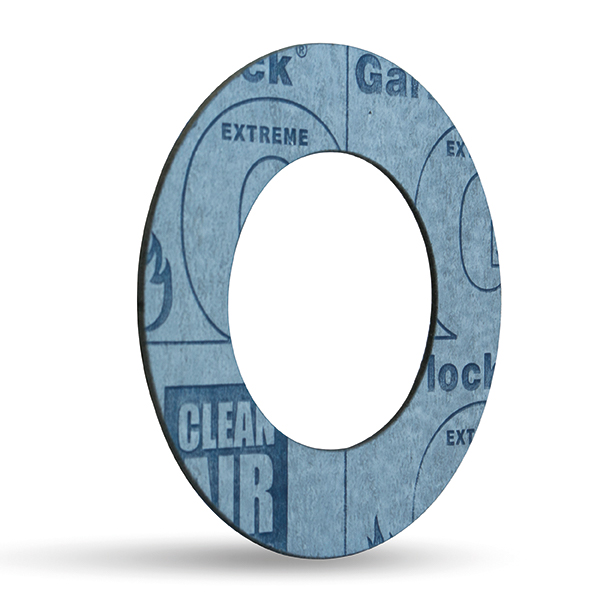

IFG 5500

Inorganic fiber gasketing with excellent thermal stability and torque retention for optimal sealability in temperatures up to 290°C (550°F) continuous.

Certificates

- DVGW VP 401

- TA-Luft with blow-out resistance

- ABS (American Bureau of Shipping)

- API

- ISO 10497 (Fire-Safe)

Features & Benefits

-

Tighter seal

-

Excellent thermal stability with minimal weight loss

-

Reduced creep relaxation and improved torque retention provide optimal sealability

-

Temperature resistant

Specifications

- Maximum Temperature: 427 °C / 800 °F

- Continuous maximum Temperature: 288 °C / 550 °F

- Minimum Temperature: -73 °C / -100 °F

- Maximum Pressure: 83 bar / 1200 psig

HTC 9850

High Temperature Gasketing. Heat and oxidation resistant carbon fiber gasketing excels in harshest conditions – intense heat, high pressure, saturated steam and hot oils.

Certificates

- ISO 10497 (Fire-safe)

Features & Benefits

-

Excels in the harshest conditions – intense heat, high pressure, saturated steam and hot oils

-

Laboratory-tested for fire safety

-

Long-lasting seal

Specifications

- Maximum Temperature: 482 °C / 900 °F

- Continuous maximum Temperature: 343 °C / 650 °F

- Minimum Temperature: -75 °C / -100 °F

- Maximum Pressure: 138 bar / 2000 psig

G-9900

Graphite fiber gasketing withstands extreme temperature and pressure, provides good chemical resistance and is

fire safe. Handles and cuts more easily than exfoliated graphite sheet or metalinserted gasket materials.

Certificates

- DVGW VP 401

- TA-Luft with blow-out resistance

- DIN EN 13555 characteristics

- ABS (American Bureau of Shipping)

- API

- ISO 10497 (Fire-Safe)

Features & Benefits

-

Withstands extreme temperatures and pressures, as well as many chemicals

-

Long-lasting seal

Specifications

- Maximum Temperature: 537 °C / 1000 °F

- Continuous maximum Temperature: 343 °C / 650 °F

- Minimum Temperature: -75 °C / -100 °F

- Maximum Pressure: 138 bar / 2000 psig

Find item-numbers and specifications in our webshop: Fiber Gaskets & Sheets

Garlock GmbH

Falkenweg 1

41468 Neuss

Germany

+49 2131 349-0

garlockgmbh @ garlock.com

© 2025 Garlock GmbH, Germany

![]() An ENPRO Company

An ENPRO Company

www.garlock.com

Garlock Europe Webshop

www.garlock.eu.com

Career Site Europe

www.garlock-karriere.de/en