Semiconductor Manufacturing

Download Semiconductor Flyers: GYLON® Style 3545 | STRESS SAVER® Style 3522 | Case Study

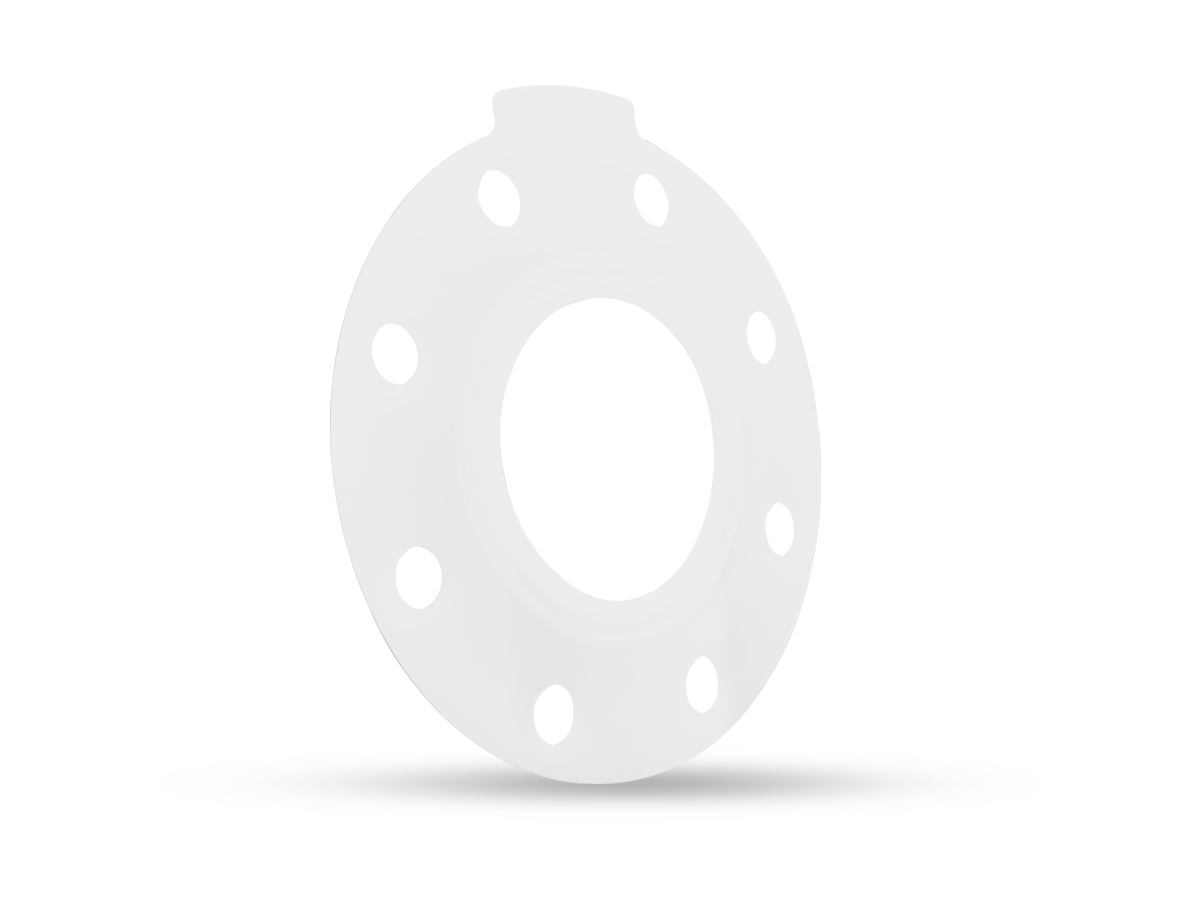

GYLON® Style 3545

Semiconductor manufacture – exhaust tool hook up

Many chemicals are used in the processing of semiconductors. Their vapours and fumes are extracted via the exhaust tool hook up to the scrubbing and recovery systems. Gaskets used on the exhaust tool hook up must be chemically resistant and physically resilient. Issues and problems can occur if the gaskets are not sufficiently chemically resistant and physically resilient.

GYLON® 3545 outperforms other gasket materials in use on exhaust tool hook ups, giving safety, performance, and cost benefits. GYLON® 3545 is a high performance gasketing material made of multi-layered PTFE for permanent resilience. GYLON® 3545 has a central core of a hard PTFE pressure resistant layer with soft compressible micro-cellular PTFE outer layers. GYLON® 3545 shows better resilience and physical properties compared to virgin PTFE and ePTFE.

GYLON® 3545 is 100% PTFE and compatible with the chemicals used and their biproducts. This includes hydrofluoric acid, hydrochloric acid, nitric acid, sulphuric acid, ammonia, ammonium salts, calcium salts.

Key Benefits

| » Excellent chemical resistance |

| » High resilience |

| » Stopped cold flow |

| » High pressure & vacuum duties |

| » Pressure and vacuum duties |

| » Temperature -268°C to +260°C |

| » 17 N/mm2 minimum load, 140 N/mm2 maximum load |

STRESS SAVER® Style 3522

Semiconductor Ultra Pure Water (UPW), acid handling and neutralisation

Ultra Pure Water (UPW), and acid handling and neutralisation are critical to the manufacturing of semiconductors. Pipework for these processes maybe stainless steel or non-metallic, for example PVDF. The seals for the pipework must meet high purity standards, be chemically compatible with process media, and seal effectively at low bolt load.

STRESS SAVER® 3522 outperforms other seal types giving safety, performance, and cost benefits.

The moulded raised ribs on STRESS SAVER® 3522 help to create a tighter seal by concentrating the compressive load.

STRESS SAVER® 3522 shows better resilience and physical properties compared to virgin PTFE and ePTFE.

STRESS SAVER® 3522 is 100% PTFE and compatible with the chemicals used and their biproducts.

Key Benefits

| » Excellent chemical resistance |

| » High resilience |

| » Stopped cold flow |

| » Suitable for metallic and non-metallic piping with either flat or raised face flanges. |

| » Ideal for non-metallic pipework PVC, FRP, PVDF, CPVC, PP |

| » Homogenous construction – single piece design to avoid permeation, delamination, or fold over of envelope construction |

| » Temperature -268°C to +260°C |

GYLON® Style 3545

Case Study: Semiconductor Manufacturing

Industry

Semiconductor

Customer

A major semiconductor manufacturer.

Background

The customer utilized expanded PTFE gaskets for their exhaust tool hookup applications. This application involves a mix of chemicals, byproducts, and exhaust fumes.

The flanges in this application are PTFE-coated stainless steel ducting, carbon steel, stainless steel, FRP, and CPVC. Due to the low-load nature of the majority of these flanges, a soft, compressible gasket is required.

Challenges faced

Fluid permeating through the body of the ePTFE gaskets was commonplace. Leaks frequently occurred in the manufacturer’s low-load flange applications, and a better sealing solution was needed.

Operating Conditions

1. Temperature: 65°C (150°F)

2. Application: Flange – Non-metallic. Exhaust Tool Hookup. PTFE line systems, carbon steel, stainless steel, FRP and CPVC piping

3. Media: Hydrochloric Acid and Sulfuric Acid, 10-75%, 260°C (500°F) and below

4. Pressure: 1 bar (15 psi)

Solution and Benefits

The manufacturer replaced the ePTFE gaskets with Garlock GYLON® 3545. Since implementing this solution, the manufacturer has had zero issues with leaks in this application. While GYLON® 3545 is similar in feel and compressibility to ePTFE gaskets, its microcellular construction and rigid PTFE center core prevent permeation through the body of the gasket. Thanks to GYLON® 3545, the semiconductor manufacturer eliminated leaks, improved safety and reliability, and reduced maintenance costs.

Garlock GmbH

Falkenweg 1

41468 Neuss

Germany

+49 2131 349-0

garlockgmbh @ garlock.com

© 2025 Garlock GmbH, Germany

![]() An ENPRO Company

An ENPRO Company

www.garlock.com

Garlock Europe Webshop

www.garlock.eu.com

Career Site Europe

www.garlock-karriere.de/en