Battery Manufacturing

Lithium Value Chain Sealing Solutions

Gaskets | Mechanical Seals | Bearing Isolators | Oil Seals

Across lithium extraction, refining, manufacturing, and recycling, Garlock solves complex challenges throughout the lithium battery value chain. By combining deep expertise in materials engineering with extensive knowledge of fluid sealing applications, we deliver innovative solutions that improve productivity, reduce costs, and comply with stringent environmental regulations.

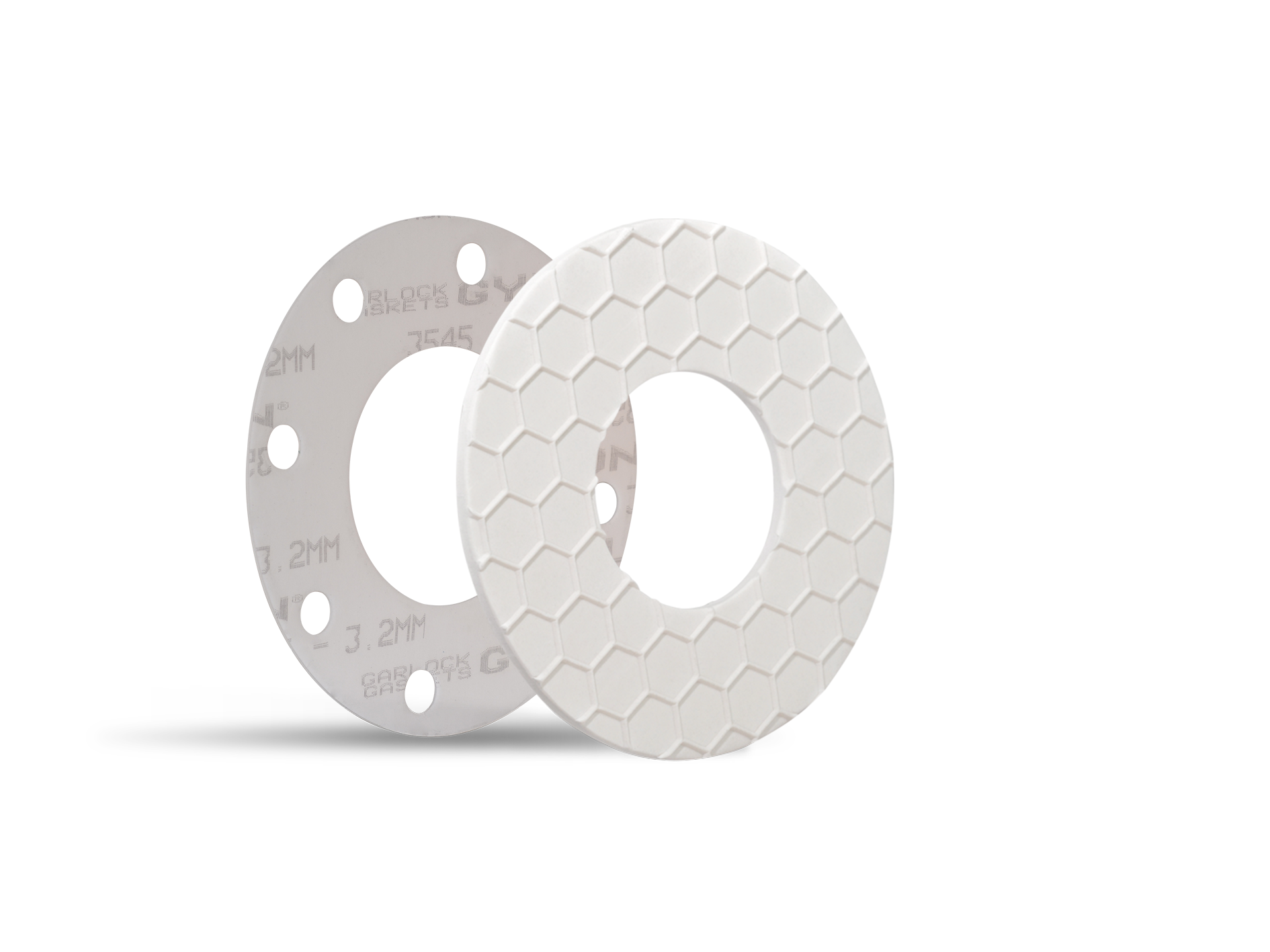

Lithium Brine Evaporation

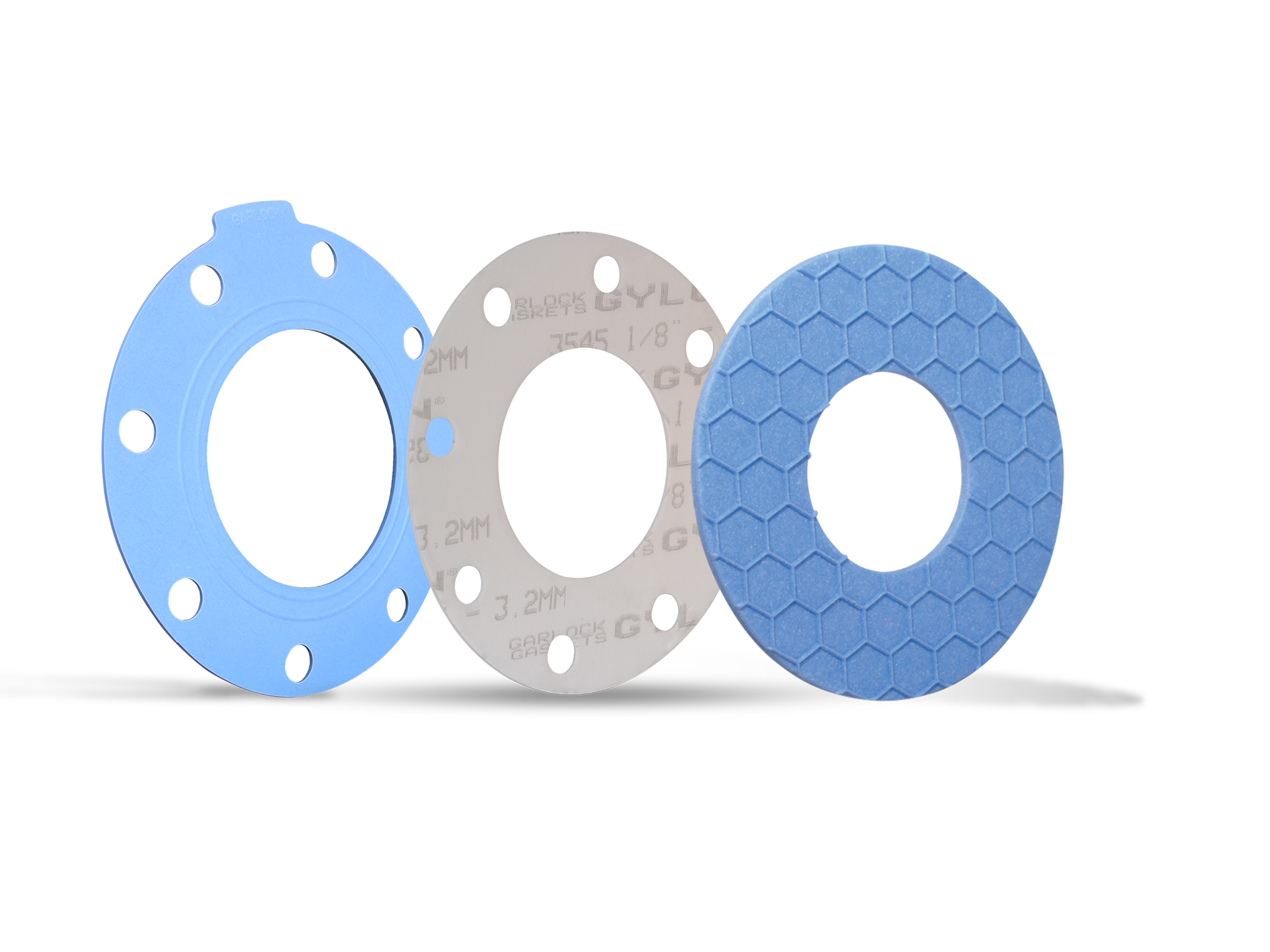

GYLON® 3545 Microcellular & GYLON EPIX®

| » Avoid premature failure even under abrasive conditions. |

| » In your most abrasive applications, consider upgrading to GYLON® 3545, a highly compressible microcellular PTFE with a rigid PTFE core for improved handleability. |

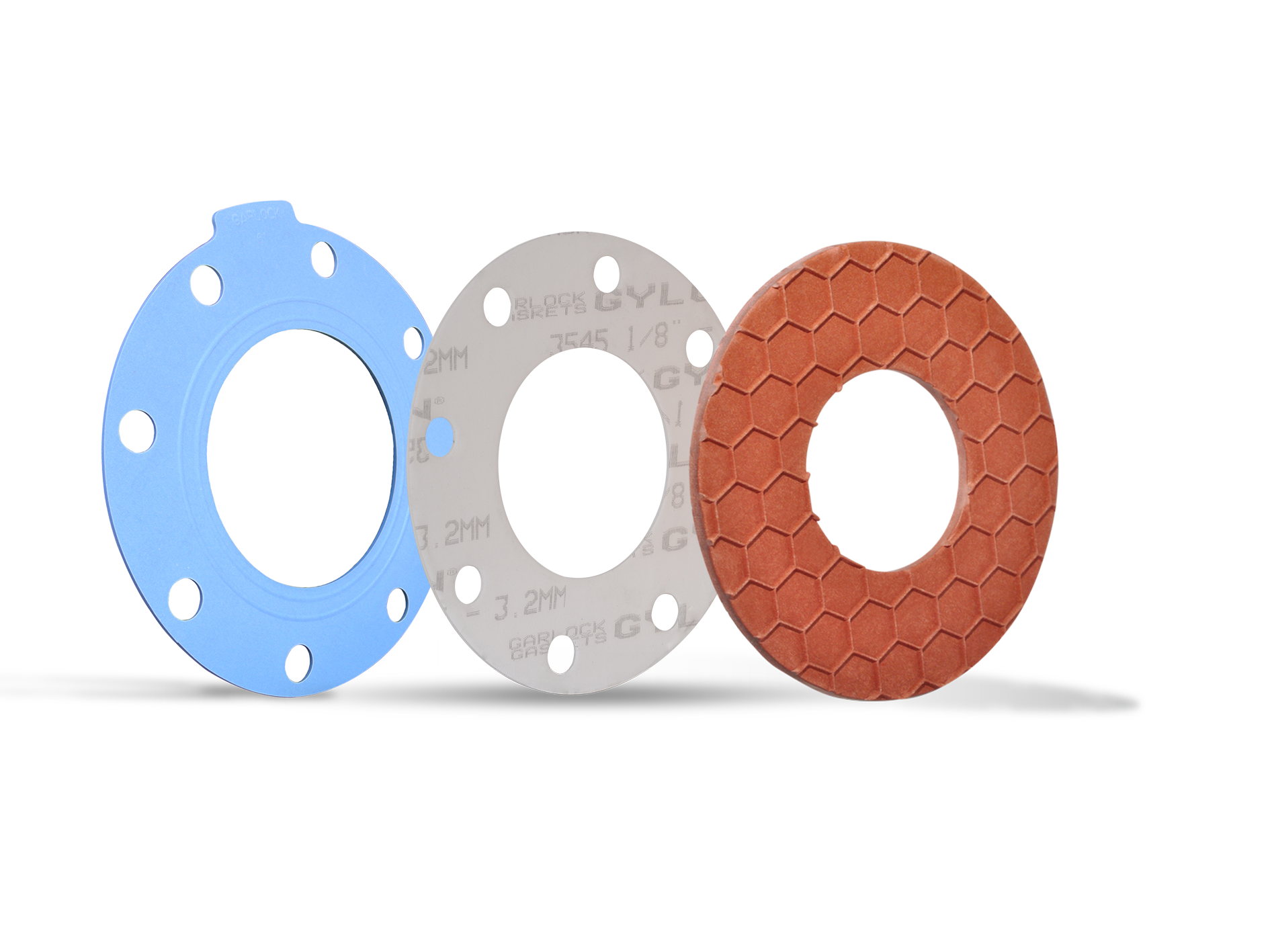

Lithium Ore Mine

GYLON® Gaskets & MILL-RIGHT® Oil Seals

| » For Lithium Ore Mining applications, Garlock’s heavy-duty sealing solutions increase safety, uptime and service life. |

| » With a focus on performance and reliability in even the most formidable conditions, Garlock sealing products provide reliable service for abrasive materials and environments. |

| » Our GYLON® gaskets are ideal for media involving sulfuric and hydrochloric acids. |

| » We also offer dynamic sealing products, including our MILL-RIGHT® oil seals that offer the best in abrasion resistance, the lowest wear, and exceptional chemical resistance. |

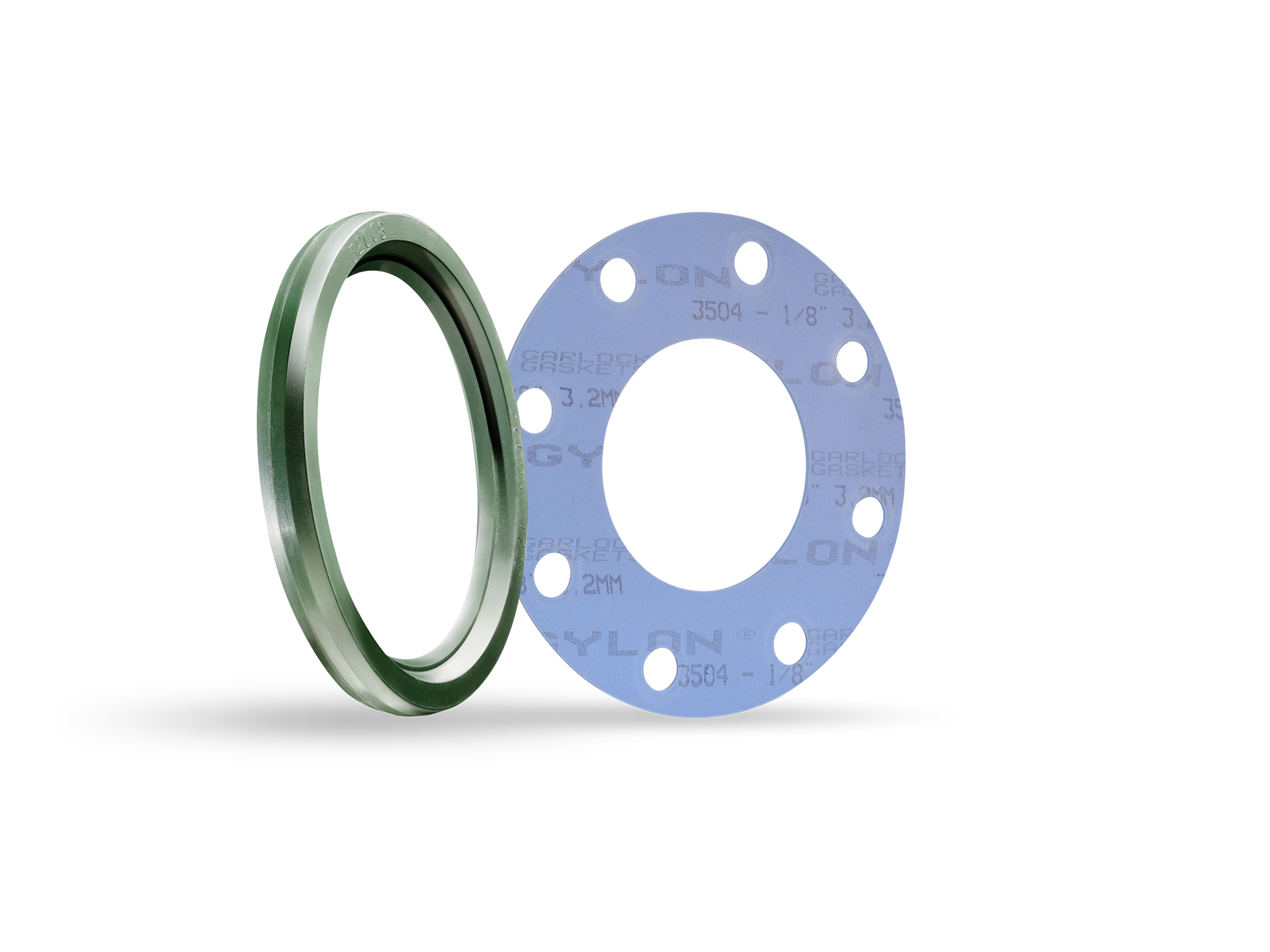

Lithium Refining

STRESS SAVER® 3504, GYLON® 3545 Microcellular, GYLON EPIX®

| » In abrasive applications, you need reliable leak protection to prevent contamination, safety hazards, and loss of product and time. |

| » Trust Garlock’s robust portfolio of gasketing solutions that combine high chemical resistance with low-load capabilities. |

Lithium Battery Recycling

STRESS SAVER® 3504, GYLON EPIX®, GYLON® 3545 Microcellular

| » Successful recovery of valuable lithium battery materials requires specialized processing, posing unique sealing challenges. |

| » Leakage issues present significant safety risks. Garlock’s solutions provide unmatched chemical resistance for sealing integrity and are well suited for low load applications common in the LIB recycling process, allowing you to safely extract resources for future use. |

Garlock GmbH

Falkenweg 1

41468 Neuss

Germany

+49 2131 349-0

garlockgmbh @ garlock.com

© 2025 Garlock GmbH, Germany

![]() An ENPRO Company

An ENPRO Company

Garlock Global Website

www.garlock.com

www.garlock.com

Garlock Europe Webshop

www.garlock.eu.com

Career Site Europe

www.garlock-karriere.de/en