GYLON EPIX® Gaskets & Sheets

The next level in PTFE gasketing

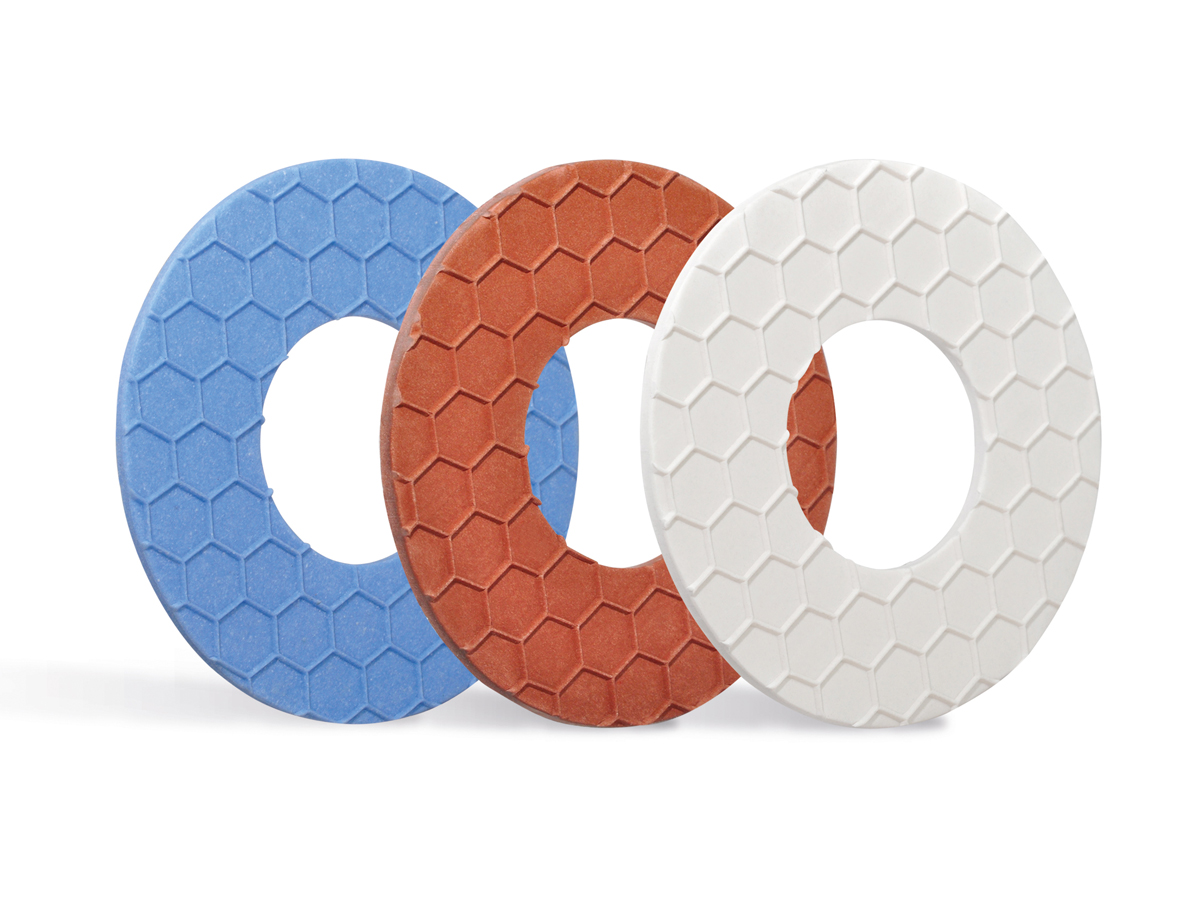

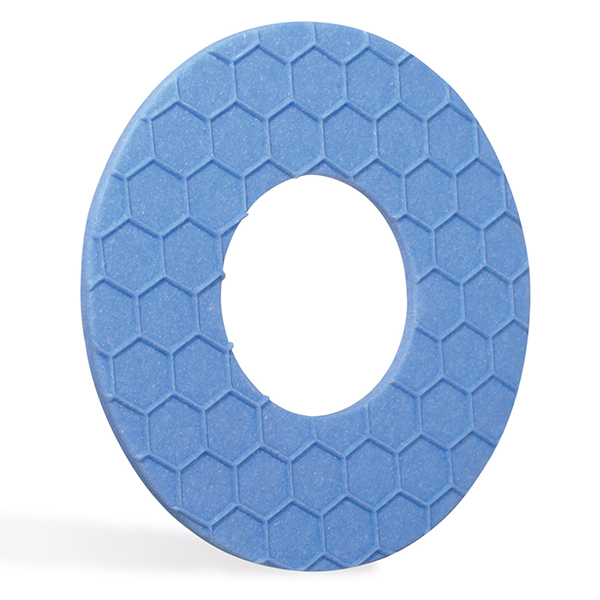

GYLON EPIX® is a newly developed family of PTFE gaskets. It is manufactured using a patented, profiled surface based on our proven GYLON® Standard, Blue and White, to create highly conformable materials for optimum sealing performance. The innovative GYLON EPIX® provides superior functional performance by combining the traditional attributes of GYLON® with an innovative surface design. It offers a broader range of applications than traditional PTFE gaskets. GYLON EPIX® delivers the sealing and load retention properties of 1/16” and the conformability of 1/8”. The hexagonal profi le provides improved compressibility and recovery. The profi led surface reduces the contact area during initial compression to concentrate the compressive force and to generate high-density-zones within the material, for improved sealability.

Designed for increased compressibility, GYLON EPIX® improves performance in misaligned fl anges. The consolidation of two thicknesses to one reduces the need to inventory multiple thicknesses. Doing so, GYLON EPIX® also reduces time and effort to upheld and re-work plant standards and piping class calculations. Garlock is dedicated to providing real sealing solutions that meet real world sealing needs. With an improved design, color-coded materials and a single thickness, GYLON EPIX® makes sealing easier.

GYLON EPIX® Gaskets & Sheets

GYLON EPIX® Style 3501-E

GYLON EPIX® Style 3501-E is a high performance, silica filled PTFE sheet material designed for use with strong acids, solvents, hydrocarbons, and other aggressive media. GYLON EPIX® Style 3501-E withstands a wide range of chemicals for extended service in a wide variety of applications.

Features & Benefits

-

Higher sealability – Ultra low emission

-

Reduced product loss

-

Inventory simplifi cation – „One fi ts all“

-

More forgiving – Easy Installation

-

Increased safety window

-

Improved load retention

-

Better compensation

-

Higher surface pressure with less load

-

Higher max. load tolerated

-

Improved compressibility and recovery

-

Unique gasketing material

-

Trusted GYLON® material

-

Suitable for low-load applications*

-

Seals imperfect flanges (Worn and pitted)

-

No intrusion/recession

-

Excellent chemical resistance

-

Stopped cold flow

-

Wide temperature and pressure range

*Depending on product and application details.

Specifications

- Temperature: -268 °C to +260 °C

- Pressure: up to 83 bar

- Thickness: 2,4 mm

- Patented hexagonal profile

- 5 MPa (N/mm²) minimum load

- 230 MPa (N/mm²) maximum load

- Compressibility (average): 47%

- Recovery: 17%

GYLON EPIX® Style 3504

GYLON EPIX® Style 3504 is a high performance, aluminosilicate microsphere filled PTFE sheet material designed for use in moderate concentrations of acids, and caustics, as well as hydrocarbons, refrigerants, and more. GYLON EPIX® Style 3504 withstands a wide range of chemicals for extended service in a wide variety of applications.

Features & Benefits

-

Higher sealability – Ultra low emission

-

Reduced product loss

-

Inventory simplifi cation – „One fi ts all“

-

More forgiving – Easy Installation

-

Increased safety window

-

Improved load retention

-

Better compensation

-

Higher surface pressure with less load

-

Higher max. load tolerated

-

Improved compressibility and recovery

-

Unique gasketing material

-

Trusted GYLON® material

-

Suitable for low-load applications*

-

Seals imperfect fl anges (Worn and pitted)

-

No intrusion/recession

-

Excellent chemical resistance

-

Stopped cold flow

-

Wide temperature and pressure range

Specifications

- Temperature: -268 °C to +260 °C

- Pressure: up to 83 bar

- Thickness: 2,4 mm

- Patented hexagonal profile

- 5 MPa (N/mm²) minimum load*

- 200 MPa (N/mm²) maximum load*

- Compressibility (average): 52%

- Recovery: 25%

* Depending on product and application details

GYLON EPIX® Style 3510

GYLON EPIX® Style 3510 is a high performance, barium sulfate filled PTFE gasketing material. GYLON EPIX® Style 3510 is designed for use were initiating and maintaining an extremely tight seal is critical; these applications include: strong caustics and moderate acids, chlorine, gases, water, steam, hydrocarbons and cryogenics. GYLON EPIX® Style 3510 withstands a wide range of chemicals for extended service in a wide variety of applications.

Features & Benefits

-

Higher sealability – Ultra low emission

-

Reduced product loss

-

Inventory simplifi cation – „One fits all“

-

More forgiving – Easy Installation

-

Increased safety window

-

Improved load retention

-

Better compensation

-

Higher surface pressure with less load

-

Higher max. load tolerated

-

Improved compressibility and recovery

-

Unique gasketing material

-

Trusted GYLON® material

-

Suitable for low-load applications*

-

Seals imperfect fl anges (Worn and pitted)

-

No intrusion/recession

-

Excellent chemical resistance

-

Stopped cold flow

-

Wide temperature and pressure range

* Depending on product and application details.

Specifications

- Temperature: -268 °C to +260 °C

- Pressure: up to 83 bar

- Thickness: 2,4 mm

- Patented hexagonal profile

- 5 MPa (N/mm²) minimum load*

- 230 MPa (N/mm²) maximum load*

- Compressibility (average): 43%

- Recovery: 18%

* Depending on product and application details

Downloads

- Declaration of Conformity FDA

- Letter of Conformance – Animal Derivates Ingredients – ADI

- Declaration of Conformity – Phthalate free, Bisphenol free

DIN EN 13555

FOOD SAFE – EC1935/2004, EC 10/2011 conformity

- GYLON EPIX® Style 3501-E – Grease Production

- GYLON EPIX® Style 3501-E – Petrochemical Plant

- GYLON EPIX® Style 3504 – Agricultural Chemical Industry

- GYLON EPIX® Style 3504 – Beverage processing

- GYLON EPIX® Style 3504 – Chemical Manufacturer

- GYLON EPIX® Style 3504 – Chemical processing

- GYLON EPIX® Style 3504 – Dietary supplement drinks

- GYLON EPIX® Style 3504 – Phosphate processing

- GYLON EPIX® Style 3510 – Chloralkali & Chlorine

- GYLON EPIX® Style 3510 – Colored paper production

- GYLON EPIX® Style 3510 – Monomer production

- GYLON EPIX® Style 3510 – Paper board packaging

- GYLON EPIX® Style 3510 – Process Control Valves

Garlock GmbH

Falkenweg 1

41468 Neuss

Germany

+49 2131 349-0

garlockgmbh @ garlock.com

© 2025 Garlock GmbH, Germany

![]() An ENPRO Company

An ENPRO Company

www.garlock.com

Garlock Europe Webshop

www.garlock.eu.com

Career Site Europe

www.garlock-karriere.de/en